Explore All About Industrial Oil Seals

Jul. 15, 2025

Oil seals, also known as oil lip seals, dirt seals, grease seals, shaft seals, or rotary seals, are used to fill the gaps between stationary and revolving parts of the equipment. They are designed to prevent the leakage of fluids from the machinery and inhibit contaminants from reaching these fluids. They contribute to the longevity and reliability of the equipment like engines and gearboxes in industrial equipment. This post discusses the importance of oil seals, the different types of materials that are used in the manufacturing of oil seals and many more.

Overview of Oil Lip Seals

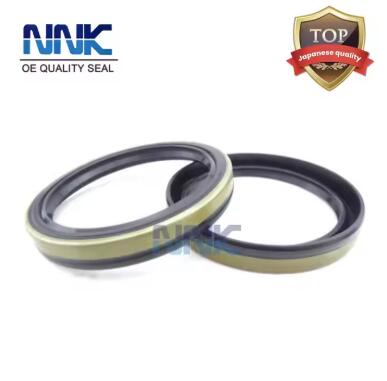

Oil seals are used to fill gaps between stationary and revolving parts of equipment, often known as radial shaft seals or rotary seals. These seals are frequently employed to keep impurities out and prevent lubricating oils, hydraulic fluids, or other liquids from escaping out of the system. An oil seal features:

Outside Metal Ring: The seal's outside metal casing helps in maintaining its shape and offers structural support.

Rubber or Elastomeric Sealing Lip: The sealing lip typically encloses the shaft in a tight seal formed of rubber or elastomeric material.

Spring: Some oil lip seals incorporate a spring to apply constant pressure against the shaft, ensuring a secure seal.

Types of Materials Used for Manufacturing Oil Seals

Oil lip seals play a significant role in several industrial applications to avoid intermixing fluids and prevent contaminants and moisture from affecting the bearings. With such a vital role to play, it is essential to choose the right material for these seals. The choice of the material will depend on factors like the type of fluid being sealed, operating temperature, pressure, and compatibility with the operating environment. The following list of materials is typical for making oil lip seals:

Nitrile (NBR): The nitrile rubber or nitrile provides excellent resistance to numerous oils and greases, including mineral grease and hydraulic oil. There are several synthetic lubricants and greases in the market based on glycol which may cause harm to NBR rubber compounds depending on their composition. Due to their excellent durability and cost-effectiveness, these seals are used in a wide range of operating conditions. However, NBR is unable to withstand exposure to acids and solvents.

Polytetrafluoroethylene (PTFE): This fluoropolymer is known by the brand name Teflon and is known to assure the best chemical resistance and exceptionally little frictional resistance. It is the material of choice for several types of rotating seals used in the chemical, food, and pharmaceutical industries.

Polyurethane (PU): Polyurethane seals offer excellent abrasion resistance and durability. They are suitable for high-pressure applications and provide good resistance to hydraulic oils. Polyurethane oil seals are often used in hydraulic and pneumatic systems.

Viton: The exceptional resilience of Viton against chemicals, strong fluids, and high temperatures is well recognized and makes this a great material for creating seals for demanding applications. This material is known to maintain its flexibility, strength, and shape even in the harshest situations. When designers and engineers use oil lip seals for industry made of Viton material, their durability and dependability guarantee reduced downtime, improved performance, and a competitive advantage. It works effectively in applications involving severe chemicals, synthetic oils, and fuels.

Ethylene Propylene Diene Rubber: This elastomer is used for creating oil lip seals for industry and other sealing elements such as U-cups. The oil lip seals made of this material would exhibit excellent resistance to steam, hot water, washing agents, and polar organic solvents. They are used to seal phosphate ester hydraulic fluids, such as Skydrol. These seals are not recommended for petroleum-based fluids, and can be effectively used with acetone, steam, alkalies, and dilute acids.

How Oil Seals Work

Industrial Oil seals work by filling the space around the parts with which they are used. When placed around a shaft, for instance, the oil seal will form a barrier that contains the shaft’s oil while simultaneously preventing external environmental contaminants from entering the shaft.

When the shaft rotates, the oil seal’s lip follows the shaft’s surface, maintaining a dynamic seal. The garter spring ensures constant contact between the lip and the shaft, providing the necessary radial tension to create an effective seal. This design ensures that lubricants are retained, friction is reduced, and wear and tear are minimized.

Parts of an Oil Seal

They may look like ordinary O-rings consisting of a single piece of elastomeric material, but oil seals feature multiple parts. Oil seals typically feature a lip, case and spring.

The case is the part of an oil seal that holds it in place. The spring is a ring of energized material that provides radial tension. Finally, the lip is an outer rim or edge that serves as the primary sealing element. Once installed, the lip will sit directly on the surface of the shaft while the spring applies tension.

In Conclusion

Oil seals do a lot of heavy lifting to keep machines running smoothly. Their main job is to keep oil and other lubricants where it belongs. Additionally, oil seals keep out dirt, water and other junk from reaching machinery parts, which could otherwise result in damage.

89

0

0

Comments

All Comments (0)