Why Tape Drywall Joints?

Is It Necessary To Tape Drywall Joints?

When it comes to installing drywall, one question that often arises is whether it is necessary to tape the joints. The simple answer is yes, it is absolutely necessary to tape drywall joints. Taping the joints helps to create a smooth and seamless surface, preventing cracks and ensuring a professional finish. In this article, we will delve deeper into why taping drywall joints is essential and the benefits it offers.

Why Tape Drywall Joints?

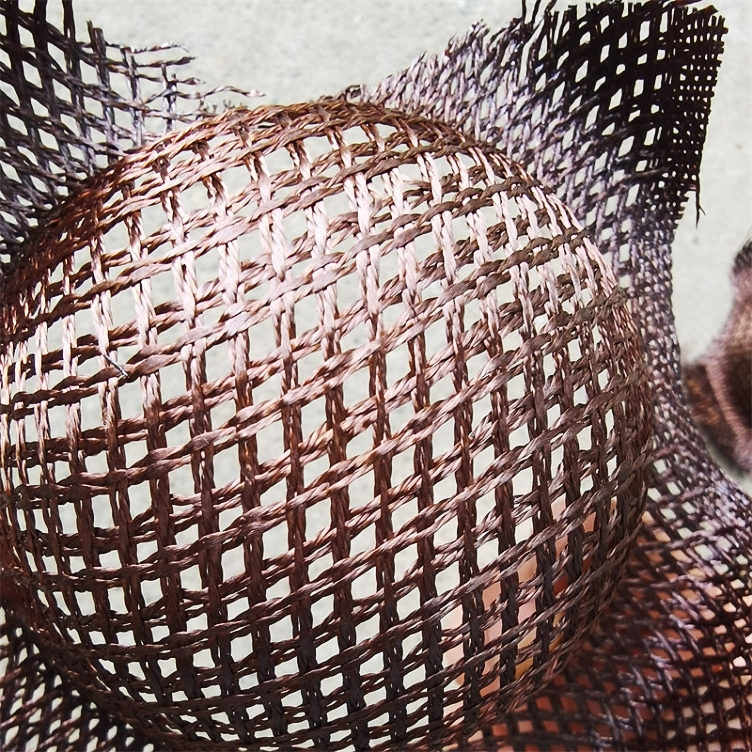

Drywall is made up of large, flat panels that are used to construct walls and ceilings. These panels are joined together at the seams to create a continuous surface. However, without taping the joints, these seams would be visible and prone to cracking over time. Taping the joints helps to hide these seams and create a seamless appearance.

1. Reinforces the Joints:

When drywall panels are joined together, there is a slight gap between them. This gap is filled with joint compound, which is then covered with joint tape. The tape acts as a reinforcement, preventing the joint compound from cracking and crumbling under stress. Without tape, the joint compound would be more likely to separate from the panels, leading to visible cracks.

2. Provides Stability:

Taping the joints adds stability to the overall structure of the drywall. It helps to distribute the stress across the joint, preventing the panels from shifting or moving over time. This stability is crucial for maintaining the integrity of the walls or ceilings, ensuring they remain sturdy and secure.

Explore more:Minerals & Metallurgy

3. Creates a Smooth Surface:

The Benefits of Polished Stainless Steel: A Shining Example of Versatility

What Is the Maximum Weight a Railway Track Can Support?

Understanding the Composition of Tungsten Carbide Rod

Aluminum Casting: Crafting Excellence in Metal

The Advantages of Hot Rolled Steel Plates

13 FAQ About MPP Power Pipe

By taping the joints, a smooth and even surface can be achieved. The tape helps to bridge the gap between the panels, creating a seamless transition. This is especially important when it comes to applying paint or wallpaper, as any imperfections or seams would become highly visible. A well-taped joint provides a clean canvas for finishing touches.

4. Prevents Cracks and Popping:

Taping the joints is vital for preventing cracks and popping in the drywall. As the building settles or experiences temperature changes, the materials can expand and contract. Without tape, these movements can lead to visible cracks in the joint compound and even cause the tape to peel away. Properly taped joints ensure greater durability and longevity, reducing the need for repairs in the future.

In conclusion, taping drywall joints is an essential step in the installation process. It reinforces the joints, provides stability, creates a smooth surface, and prevents cracks and popping. Without tape, the joints would be visible and prone to damage, compromising the overall quality of the installation. Therefore, it is crucial to invest time and effort into properly taping drywall joints.

If you are looking for a reliable drywall joint tape supplier, do not hesitate to contact us. Our company offers high-quality tapes that are specifically designed for drywall applications. With our products, you can ensure a professional finish and long-lasting results. Whether you are a contractor or a DIY enthusiast, we have the right tape for your needs. Contact us today to learn more about our products and place an order.

Remember, when it comes to taping drywall joints, don't cut corners. Invest in quality products and techniques to achieve the best results. Happy taping!

What are the difference between ball bearings and roller bearings?

What are the advantages of using galvanized steel coils?

Why has the demand for custom aluminum coils surged?

How long will Galvalume Steel Coil last?

What are the advantages of Galvalume steel coils?

Why is Flux Used in Aluminum Casting?

How Does a Simple Magnetic Motor Work?

194

0

0

Previous: What is window screen mesh?

Next: What is Wear Plate?

Related Articles

Comments

All Comments (0)